3D Printed Printers has transformed the way we conceive and produce items. This cutting-edge technology allows users to create objects by stacking materials in accurate shapes and sizes. Industries across the globe are employing it to enhance production methods and lower expenses. From healthcare to automotive, 3D offers limitless opportunities.

Thanks to its capacity to produce complex patterns, 3D Printer Technology has fascinated both companies and individuals. This piece explores thoroughly the functionality, uses, and advantages of this advanced innovation. By the conclusion, you’ll grasp how 3D printed printers are influencing the future of manufacturing.

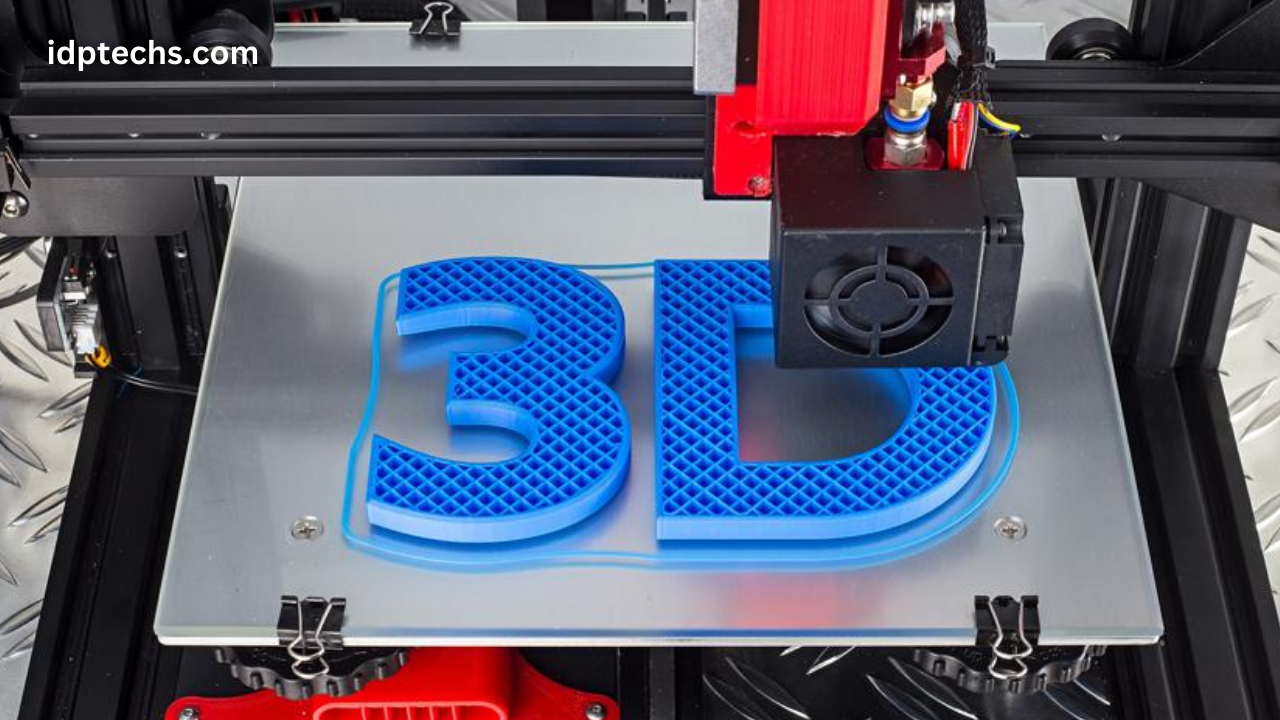

3D Printed Printer Technology

3D Printers Technology involves generating three-dimensional items from digital designs. It employs additive manufacturing, which involves adding materials layer by layer to create the intended shape. In contrast to conventional techniques, it reduces waste and provides outstanding accuracy.

This technology depends on 3D Printed Printers that interpret digital designs made with CAD (Computer-Aided Design) software. Substances like plastic, resin, metal, or ceramics are fused and layered in successive deposits. The outcome is a completely operational or prototype item prepared for use.

How Do 3D Printed Printers Work?

These printers follow a systematic process:

- Designing the Model: A digital design is created using CAD software. This file is the blueprint for the object.

- Slicing the File: The CAD model is sliced into horizontal layers. This step helps the 3D Printed printer understand how to construct the object layer by layer.

- Printing the Object: The 3D Printed Printer heats the chosen material and deposits it precisely onto the build platform. This process repeats until the object is complete.

- Post-Processing: Once printed, objects may undergo additional finishing, like sanding or painting, to enhance quality.

3D Printers Uses

Healthcare Centre

3D Printer Technology revolutionizing the medical sector by producing prosthetic devices, implants, and surgical instruments. Physicians currently utilize 3D models to meticulously plan intricate surgeries.

Automotive and Aerospace

Automakers and aerospace engineers utilize 3D Printed Printer To produce lightweight, resilient parts. It shortens production time and guarantees economical manufacturing.

Education and Investigation

Educational institutions employ 3D Printer Technology for practical learning and research activities. This technology promotes creativity among learners.

Fashion and Art Industry

Designers and artists utilize 3D Printed Printers to create complex jewelry, sculptures, and even apparel. This approach offers artistic liberty and distinctive styles.

You will also like:

Benefits of 3D Printed Printer Technology

Customization

3D printed Printers enable tailored manufacturing. From customized medical devices to distinctive home furnishings, the options are limitless.

Cost-Efficiency

Conventional manufacturing typically necessitates costly molds and tools. 3D Printed Printers remove this requirement, greatly lowering expenses.

Sustainability

Additive manufacturing minimizes material wastage. Many 3D printed printer materials are also recyclable, supporting eco-friendly practices.

Quick Prototyping

3D-printed devices facilitate rapid prototyping, enabling companies to evaluate and enhance products effectively prior to large-scale manufacturing.

Challenges and Limitations

Although it has benefits, 3D Printer Technology encounters specific hurdles:

- Significant Upfront Expenses: Acquiring industrial-level 3D Printed devices can come with a high price tag.

- Material Constraints: Not every material works well with 3D Printer Technology Machines.

- Skill Requirements: Operating and designing 3D devices requires specific expertise.

Future of 3D Printed Printer Technology

The outlook for 3D Printer Technology seems optimistic. With ongoing developments, printers are becoming quicker, less expensive, and more adaptable. Innovative substances like biodegradable plastics and metal alloys are broadening the uses of the technology. Sectors such as construction are exploring 3D printed houses, leading to wider acceptance.

Final Thoughts

The technology of 3D printed printers is revolutionizing contemporary manufacturing. It enables sectors to create new solutions, cut expenses, and adopt sustainability. Its uses in healthcare, automotive, and education showcase its adaptability and possibilities.

As innovations progress, the potential of 3D printed printers is endless. This technology not only transforms our methods of creation but also fosters a future where creativity blends with reality.

FAQs about “3D printed printers”

1. What materials can 3D printed printers use?

3D Devices can employ various materials, including plastics, resins, metals, ceramics, and even sustainable polymers. The choice depends on the purpose of the object and the kind of printer.

2. Are 3D printed products durable?

Yes, 3D printed items are resilient when crafted with premium materials. In numerous instances, their durability is comparable to that of conventional manufacturing.

3. Can individuals afford 3D printed printers?

Basic 3D Printed printers for personal use are budget-friendly, priced starting at $200. Nevertheless, industrial-grade models are pricier and designed for professional uses.